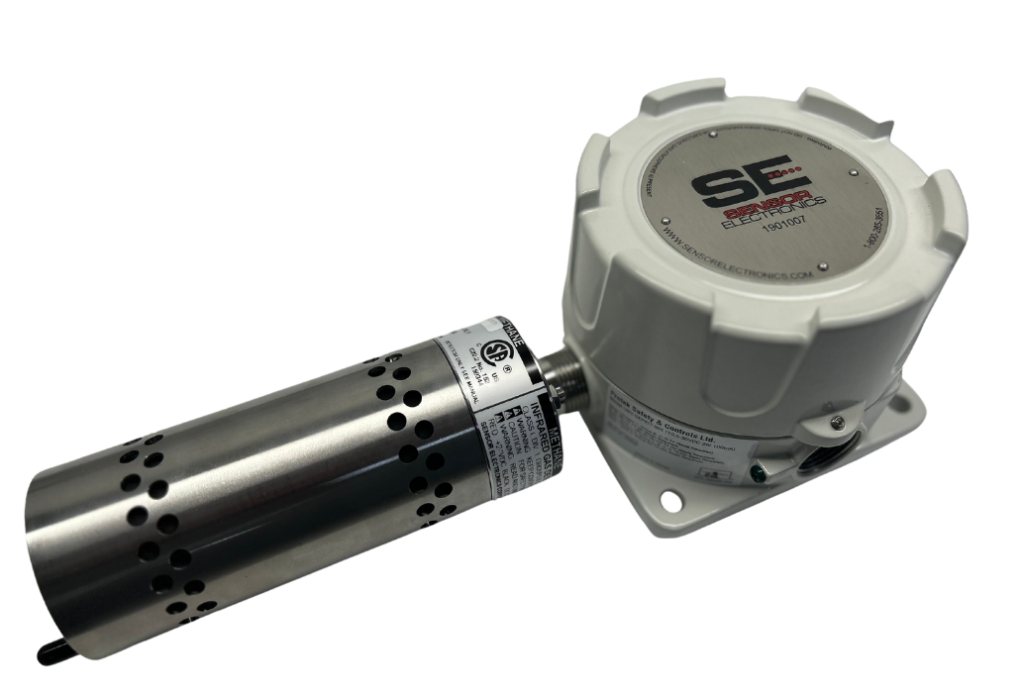

SEC MILLENIUM HAWK Hydrocarbon Gas Detector

The SEC Millenium Infrared Hydrocarbon Gas Detector is a complete self-contained optical hydrocarbon gas detector. The sensing and reference elements are self-compensating for optical integrity and other signal inhibitors. The SEC Millenium Hydrocarbon infrared gas detector can operate as a stand-alone 4-20mA gas detector, or it can be coupled with a Sensor Electronics 3100 Transmitter Display.

Specifications

| Construction: | 316 stainless steel Optional nickel plated aluminum |

| Accuracy: | +/- 3% LFL, 0 to 50% LFL (Lower Flammable Limit) +/- 5% LFL, 51 to 100% LFL |

| Operating Temperature Rating: | Certified Temperature Range: -40° to +70°C Factory Function Tested: -55° to +70°C 0 to 99% RH (non-condensing) |

| Operating Range: | 18 to 32 VDC measured at the detector head |

| Power Consumption: | 3.6 Watts Max Current Draw: (at 24VDC) Average: 85 mA Peak: 150 mA |

| Approvals: | C22.2/UL 60079-29-1 Performance Tested Class I, Div 1 | Groups B, C, D | T5, Methane 0-100% LEL Installation Category: Cat. I, Pollution Degree 2 |

| Available gases: | Propane, Propylene, Methane, n-Butane, Ethane, Gasoline, Ethanol, Isopropyl Alcohol, Ethylene, Methanol, Aeromatic 150, Pentane, Hexane, Cyclopentane, Isobutane, Toluene, Methyl Amyl, Ketone, P-Xylene, MEK, Tert-Butyl Acetate.

Please note that this list is not all-inclusive. For more information please contact Protek Safety & Controls Ltd |

| Protek Quick Delivery | P/N: 49000000100-L12E (Sensor Range 0-100%LEL Methane) P/N: 49000100100-L12E (Sensor Range 0-100%LEL Propane) P/N: 49001100100-L12E (Sensor Range 0-100%LEL Butane) |

Features

| Accessories | Part Numbers |

|---|---|

| Single Channel Display | UDM-001 |

| Dual Channel Display | UDM-002 |

| Sensor Separation Kit | UNV-SEPKIT-001 |

| -55°C Sensor Separation Kit | UNV-SEPKIT-004 |

| Single OR Dual Display Multi Wire Option(s)* | UDM-MWO-00X-X |

| 2-3 Wire Retro Fit Sensor Separation Kit** | UDM-MWO-SEPKIT |

*See UDM-MWO Literature for part numbers

**2-3 Wire Retro Fit Sensor Separation Kit ONLY to be used with UDM-MWO Series.

Specifications

| Detection Method: | Electrochemical and Galvanic |

| Sampling Method: | Diffusion (requires 1 liter per minute sample flow rate) |

| Output (Analog): | 4-20 mA (source type), max. 1000 Ohm load at 24 VDC supply voltage |

| Output (Digital): | Interactive Interface Available On The Calibration (White) Wire |

| Construction: | 316 Stainless Steel Explosion Proof |

| Accuracy: | +/- 5% |

| Lower Detectable Limit: | 1% of Full Scale |

| Recommended Minimum Alarm Setting: | 10% of Full Scale |

| Temperature Rating: | Toxic gas sensors temperature range may vary. See Common Gas List Table below |

| Operating Voltage: | 24 VDC |

| Operating Range: | 8 to 32 VDC measured at the detector head |

| Power Consumption: | < 2.0 Watts Max (includes Heated Sensor Option) |

| Max Current Draw : | 80mA @ 24Vdc with heated sensor cell |

| Approvals: | CSA: Class I, Div 1 | Groups B, C, D | T6 (Flameproof Version) Category: Cat. I, Pollution Degree 2 |

| Partial Gas List (over 40 gases available) | Carbon Monoxide (CO), Hydrogen Sulfide (H2S), Methanol (CH₃OH), Methyl Mercaptan (CH4S), Nitric Oxide (NO), Nitrogen Dioxide (NO₂), Oxygen (O), Sulfur Dioxide (SO2)

Please note that this list is not all-inclusive. For more information please contact Protek Safety & Controls Ltd |

| Protek Quick Delivery | P/N: 3024 0D 0100MH-F012 (Sensor Range 0-100PPM H2S) |

Features

| Accessories | Part Numbers |

|---|---|

| Single Channel Display | UDM-001 |

| Dual Channel Display | UDM-002 |

| Sensor Separation Kit | UNV-SEPKIT-001 |

| -55°C Sensor Separation Kit | UNV-SEPKIT-004 |

| Single OR Dual Display Multi Wire Option(s)* | UDM-MWO-00X-X |

| 2-3 Wire Retro Fit Sensor Separation Kit** | UDM-MWO-SEPKIT |

| Calibration Cup | CC/SG-02 |

*See UDM-MWO Literature for part numbers

**2-3 Wire Retro Fit Sensor Separation Kit ONLY to be used with UDM-MWO Series.

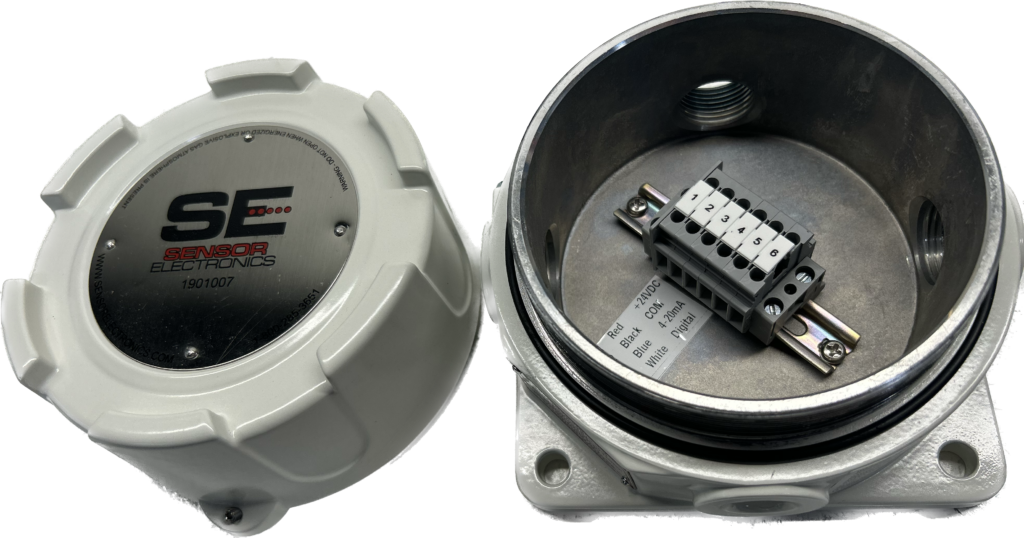

Sensor Separation Kit UNV-SEPKIT-001

The SEC Univeral Sensor Separation Kit is certified for use with Detcon or SEC Gas Detection and for use with the Protek UDM. It is a unique design certified for Zone 1 and Zone 2 installations in Canada and the USA. When installed in a Zone 2 application, no seals are required; as stated on the certification label. This allows for quick and simple field installation and remote calibration and function testing access when mounting the gas detector sensor up high or down low.

Features